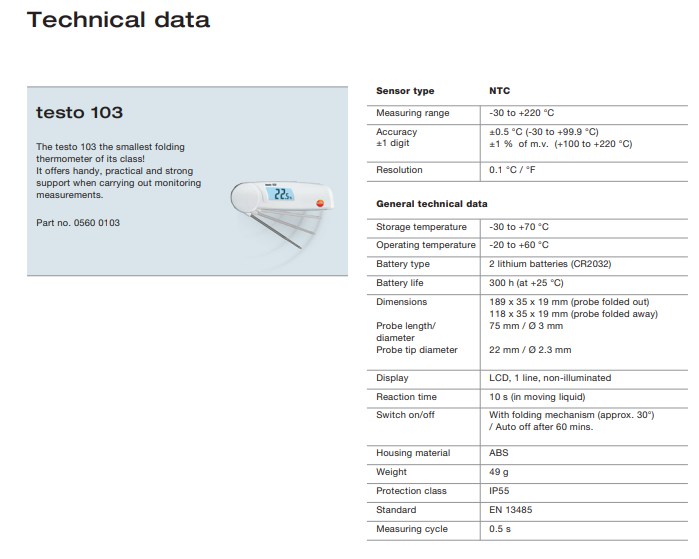

Folding thermometer

testo 103 – The smallest folding

thermometer in its class.

At a length of 11 cm, the testo 103 is the smallest folding thermometer in its class. It hardly takes up any space, so you can simply stow it in your breast or trouser pocket. That way, it is always quickly available and close to hand. The small folding thermometer is immediately ready to measure after folding out to an angle of greater than 30°, and is therefore flexible in its application. After measurement, the probe can simply be folded away and stored safely until the next measurement.

The folding thermometer testo 103 is conform to HACCP and EN 13485. Its narrow measurement tip leaves only small punctures in the foodstuffs, making it optimally suitable for spot checks – for example in production, storage and processing, in gastronomy, in supermarket chains, in food retail or in industry

Temperature measurement in food management

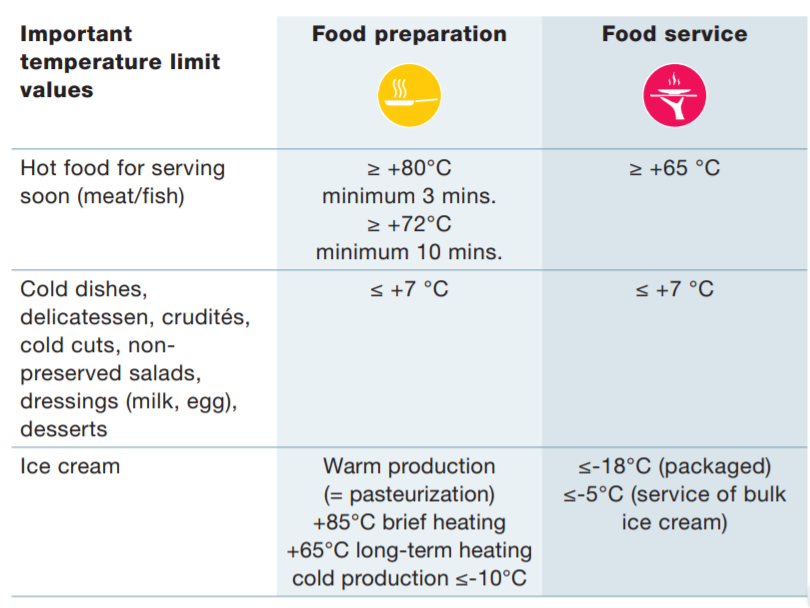

As a restaurateur, you want to serve your guests fresh and tasty dishes without any contamination by germs. You ensure this quality through two principles:

- Compliance with the cold chain for refrigerated foods

- Sufficient heating of cooked dishes

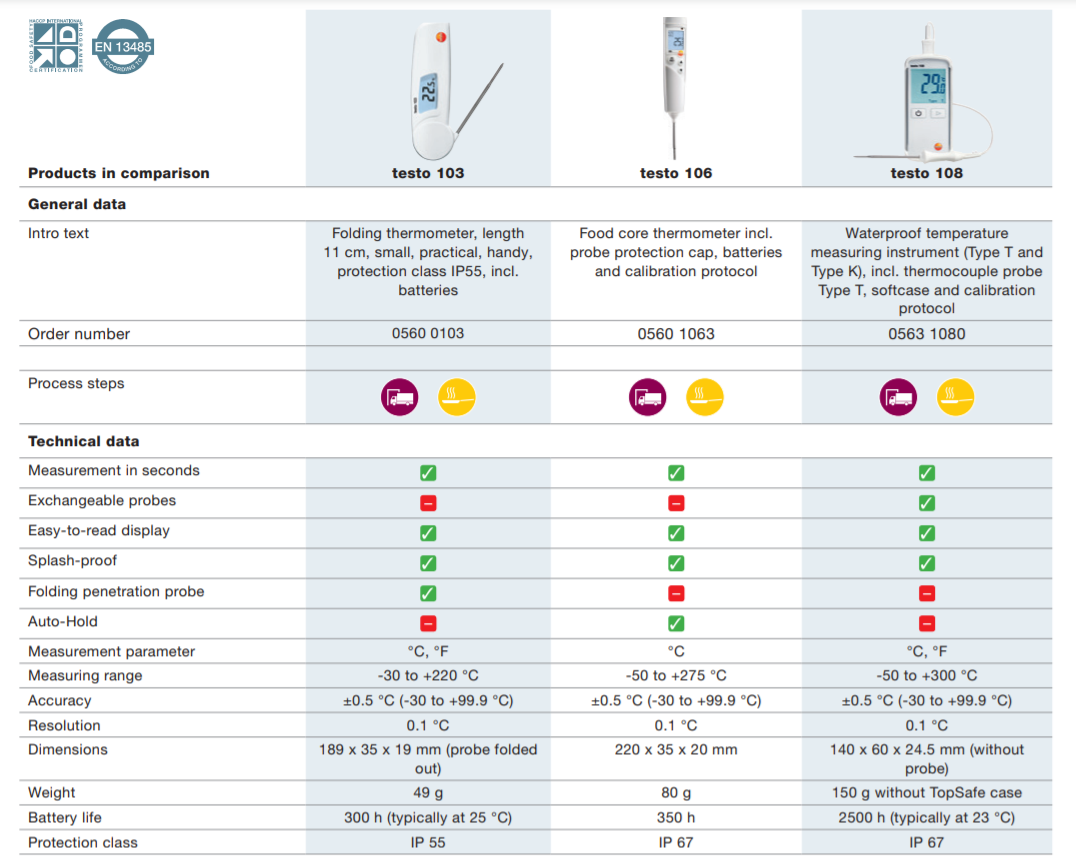

Penetration & IR thermometers available are:

Models: Testo 106 food kit, Testo 103, Testo 104, Testo 104IR, Testo 106, Testo 108, Testo 826 T2, Testo 905-T1 and many mini penetration/contact thermometer.

Description:

The time problem as a challenge in food management

In comparison to large kitchens (e.g. in hospitals, company canteens, catering operations), smaller restaurants and hotel kitchens rarely have a specially designated person with the responsibility for food safety.

This means: The head chefs and/or owners are themselves responsible for compliance with the HACCP principles and hygiene standards.

Because core tasks take up virtually all the operational capacity, HACCP tasks have to be carried out alongside them. Measuring technology solutions in this area should therefore be easy to use and reliable. Ideally, practical features can even considerably reduce the time needed for the respective tasks. For example, the acquisition of an automatic monitoring system pays off in reduced personnel costs.

The following typical tasks are established in restaurants, kitchens & canteens:

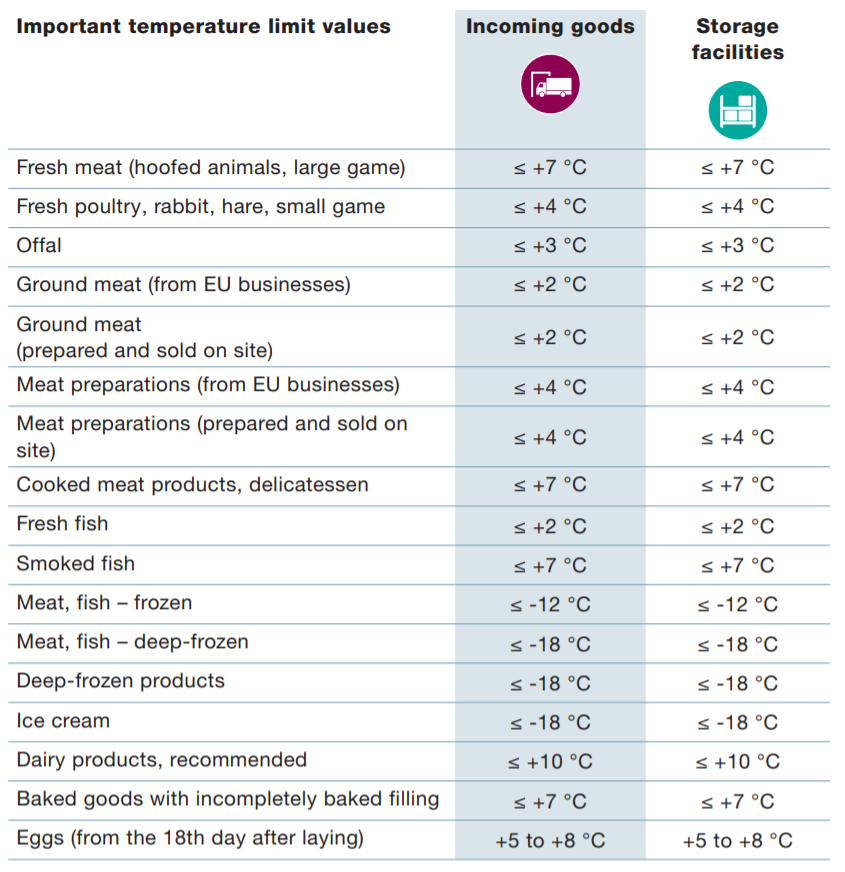

- Checking incoming goods: Have the raw materials or semi-cooked products always been adequately refrigerated?

- Storage check: Are storage rooms and cold storage cells permanently refrigerated without any failures?

- Control of meal production: Have all cooked products been sufficiently heated? Have all cold dishes and desserts been sufficiently cooled? Does the cooking oil still meet the required quality or does it need to be replaced?

- Food service: Are the dishes still hot enough before being served?